Budsaraporn Surajarusarn

Polymer Science and Technology Program Department of Chemistry Faculty of Science, Mahidol University Phuttamonthon 4 Road, Salaya Phuttamonthon District, Nakhon Pathom 73170 Thailand

Paweena Traiperm

Department of Plant Science Faculty of Science, Mahidol University Rama 6 Road, Phyathai 10400 Thailand

Taweechai Amornsakchai

- Polymer Science and Technology Program Department of Chemistry Faculty of Science, Mahidol University Phuttamonthon 4 Road, Salaya Phuttamonthon District, Nakhon Pathom 73170 Thailand

- Center of Sustainable Energy and Green Materials Faculty of Science, Mahidol University Phuttamonthon 4 Road, Salaya Phuttamonthon District, Nakhon Pathom 73170 Thailand

- Center of Excellence for Innovation in Chemistry Faculty of Science, Mahidol University Phuttamonthon 4 Road, Salaya Phuttamonthon District, Nakhon Pathom 73170 Thailand

Pineapple leaf waste is an agricultural product that is available in large quantities and is still under-utilized. Pineapple leaf fibre (PALF) has been studied as a reinforcement in polymer composites (Asim et al. 2015; Mishra et al. 2004). In addition, our group has shown that PALF, with a novel extraction method, can be used effectively to reinforce both plastics (Kengkhetkit & Amornsakchai 2014, 2012) and rubbers (Prukkaewkanjana et al. 2015). The use of pineapple leaf as a source of fibre for composite application is still very limited.

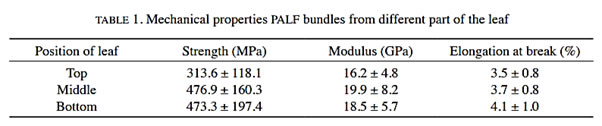

The aim of this work was to investigate the morphology, microstructure, and mechanical properties of pineapple leaf fibre (PALF) such that its full potential may be realized. Pineapple leaf, its fibre bundles and elementary fibres have been investigated. Morphology, size, and mechanical properties of fibre bundles extracted from different parts (i.e. bottom, middle and top) of a leaf were studied.

The strength of PALF is similar to that of flex and hemp fibres and thus can be used in similar applications. However, for practical use, the difference is probably too small to both cause any real problem and be worth the cost of separation.

Financial Support

The Center of Excellence for Innovation in Chemistry (PERCH-CIC), Office of the Higher Education Commission, Ministry of Education

http://www.ukm.my/jsm/pdf_files/SM-PDF-48-1-2019/17%20Budsaraporn%20Surajarusarn.pdf